|

|||||||

| General discussion about Access Virus Discussion about Virus A, B, C and TI. |

|

|

|

Thread Tools | Search this Thread | Display Modes |

|

|

|

#1

|

||||

|

||||

|

About the pots...

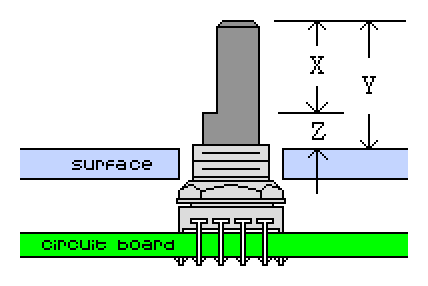

Here was my original thread, when I was trying to find the pots used (before contacting Access' hardware branch to obtain them). http://infekted.org/virus/showthread.php?t=24791 http://SynthesizerService.de stated the pots are 10K Ohm linear. These are easy to find, but ones with the same spindle dimensions as the Virus uses are not. The Virus pots have spindles that are exceptionally short.  Above shows the measurements of a general potentiometer spindle. However, for the Virus, the 'Z' measurement is 0mm (it sits flush with the top of the nut), and the 'Y' measurement is much smaller than usual. So an off-the-shelf 6-legged, 10KOhm vertical pot like this, for example...  ... (the one on the right), or the one you pointed to in Mouser (well, at least the graphic of it), wouldn't be any good, as the knob would be sticking out by a mile. At the same time you don't want the 'Y' measurement to be too small, or the bottom of the rubber knob will chafe the surface. |

|

#2

|

|||

|

|||

|

Quote:

Mouser's site even says that the image is for reference only,, that you have to refer to the specs. Looking at the specs gives you a 3d PDF of the actual item  which as you can see has a much shorter shaft. Personally, I'd rather take the chance with ordering these from Mouser, than have to pay shipping (possibly from Germany) and pay for a wire transfer or bank draft on top of that... Access, if you're reading this, you know that there is a credit card reader available for the iPad, right? :/ Last edited by Ashe35 : 01.10.2013 at 11:12 AM. |

|

#3

|

||||

|

||||

|

Yeah, the USA banks have become greedy thieves in at least my bank would charge minimum $20. just for a wire transfer, which is insane since it's all the same zeros and ones/binary. The iPad cc reader has made it really easy for we visual artists at an arts fest to accept cc without having to buy/rent a cc machine or pay crazy fees. Surprised Access does not help out the International market they criss cross!

__________________

"Language is a VIRUS from outer space" --Wm. S. Burroughs |

|

#4

|

|||

|

|||

|

Quote:

Only $20? that means its only gone up $5 in 11 years... |

|

#5

|

||||

|

||||

|

Yes, the dimensions of that does look very much like the correct one. Keep us posted.

__________________

PS > And another thing! Will the Ti|3 have user customisable/importable wavetables? |

|

#6

|

|||

|

|||

|

I'm not sure if any of you guys care, but I've solved the shaky pot problem without having to replace any pots at all with some strategically placed JB weld. the crazy glue fix that was mentioned pages ago was one I tried first a few years back and it worked pretty well for the hardly loose pots, but the looser ones loosened up after a year or so of use. I would prefer replacing the pots entirely, but I don't feel like spending $30 on pots only to find out that they don't fit right.

for the record, it was a shitty engineering choice on access' part to have the pots free standing like that, they are designed for the centre post to be screwed down with a washer and a nut on the faceplate so that they don't do what they seem to all do (ie. wear out). anyhow, I'll take some pics of my jbwelded pots in case another person happens to land on this page with the same problem (hi, person from the future!). on an unrelated note, I mailed access a while back looking for a knob and pots to buy, but they didn't have anything in stock so they took my name and address. a few months later, five free knobs and some stickers showed up in my mailbox, but no go on the pots themselves. next time I do a mousr order, I'll throw in one of those pots and let you guys know how they compare to the stock ones. /studiocat |

|

#7

|

||||

|

||||

|

I ask because did they not place a keyboard either without after touch or less responsiveness on Indigo? Wondering if so, did they use same 'free standing pots' up to the Ti2 Polar? Were Access engineers depending on the holes in keyboard fascia to maintain center axis stability? For what it's worth, learned from my military career, where indeed had sensitive nuclear security equipment that had tons of knobs to twiddle and very precise numerical combinations required; we were taught to turn/treat *any* potentiometer with respect to the axis they are all mounted on, no matter the configuration. Meaning, to this day, I only turn knobs on my synths without *any* pushing nor using for example one finger, letting the length of finger be surface the knob rolls on length of, ever so slightly creating an off-center-axis pressure that possibly could cause undue friction and failure or inaccuracies. I will say that having since acquired a waldorf Q synth rack with all those knobs, those optical pots are the most smooth and solid have twiddled to date. Interested in viewing pics of the JB Wield fix and how you managed to keep the stuff from oozing into scary places!?! I thought sharing my training of treating our synth's pots/knobs as if they were same military spec'd equipment could perhaps help others. Have seen people treating pots/knobs rather harshly on YouTube with exception of Elektron gear, whose multi-function push/turn pots are made to have already a slight 'wear-in tolerance'. Recently purchased an used Elektron MonoMachine SFX60 Mk1 (first generation) for external sequencing experimentation and firstly thought had 8 bad pots but Elektron quickly replied and have since read on their forum that their pots are made to allow for this 'off-axis' human twiddling. (deep machine by the way). Relevant rant over!

__________________

"Language is a VIRUS from outer space" --Wm. S. Burroughs |

|

#8

|

|||

|

|||

|

Step 1.

Does your cat look like this?  or like this?  No? Then rub it on its chin, between the ears, or on its belly until it starts smiling, then continue to step 2. Step 2. Place JB weld on either side of the pots like in the picture below.  less is more, but less than I have pictured is less in a bad way. more than I have is probably alright for a B/classic, as the threaded portion does not even make it to the faceplace. two out of four corners of each pot will have an empty hole, and the other two will have blue plastic knobs poking out. I am not sure how much JB weld you can pour into those holes before the pot is garbage, but unless you are good with a soldering iron, I recommend being careful. a few of my pots were had a bit seep into those holes, but I wasn't to concerned because I've been repairing electronics for a decade anyhow. Only one of the pots pictured was solid enough to not bother JB welding. I applied it to the pots like in the above picture (both sides, not just the pictured side) to about 75% of my pots, and they are solid as new. How sturdy is this fix? Well, as long as you mixed the JBweld properly and gave it a good 24 hours to cure, it should outlast the pots themselves, based on my experience with this stuff (I've gone through probably five litres of this stuff over the years). Step 3. Why does this happen?  Well, two main reasons. One, is that the metal part you can see here should protrude through the faceplate, and a washer and a nut should adhere it to the faceplace for added rigidity. If your pot is really shaky, pop off the knob and move it back and fourth. if th black plastic post moves but there is ABSOLUTELY ZERO play in the threaded metal part you can see in the picture, then this JBweld job won't do crap, and the plastic components of the pot are worn out. If the threaded cylinder does have any sort of play, it is because it wasn't mounted to a sturdy surface in the first place which is definitely access' fault. This is probably a fault you will find in other modern synths as well, and you can check to see if this design defect affects any synth by simply pulling off the knob and looking in. Is the inside of the shaft threaded? it was almost positively designed to be mounted around the collar. The second complaint is the plastic posts used in these pots. they definitely skimped out on the pots for these, and for an extra $5 worth of parts could have installed pots with a metal post. If you treat your knobs properly and the threaded collars were properly locked down, these pots would last a reasonable amount of time, so this minor complaint is greatly surpassed by the first one. If I ever break a pot completely, I'm going to order a few sturdier metal pots to experiment with, but I'm pretty sure my fix will outlast me. Step Namnibor. Please continue treating electronic devices with respect, like most people should but nobody does. It is usually pretty obvious (to completely biased me) how mechanical things are intended to be treated, so anything that twists but doesn't have any functionality by rocking should be turned, not rocked. It was after getting my virus back from lending it out that I had to fix half the pots in the first place, but to be fair, they wouldn't have done this if they were properly mounted in the first place. Again, you can see if this common design flaw exists in any knobbed thing by popping off the knob itself and seeing if the collar is threaded (most are), and if there is a nut holding that collar to something rigid as per its design. Step Future Plans. I'm not sure how you fellas feel about mods, but this summer's mod project is a pair of TOTALLY FUNKY ears for this sucker. left ear will have a pitch/mod wheel and a rather basic 16 step sequencer, and the right ear will have a one or two octave keyboard in the style of an accordion. if people on here are into that sort of thing, I'll start a thread when I'm starting on it. Step Other Questions. If I'm forgetting something or not specific enough about something, let me know. |

|

#9

|

||||

|

||||

|

This may seem a bit ~*mad*~ but perhaps an even easier and pragmatic way to *keep* the pot stems upright ALL the time, no matter what:

Without even having to open-up the Virus, providing one's pots are all okay or have been fixed per this great post--could one just remove only the knobs and place simple black anodized flat washers that are small enough to where one would not see it once knob is replaced, making sure the center hole in washer *just fits* diameter of encoder/pot stem, and affix flat washer to flat Virus fascia, centered, thus not ALLOWING any side to side play in first place? Plastic washers can even be found if friction of metal against plastic stem is a worry and super glue GEL would spread less and on that note, less of course is best, making sure it's adhered by four equal points. The tubes allow you to have needle-sized applicator. Am considering doing this as a preventative measure since both the KB and KC are far out of warranty and in event some day it were necessary to open the hood and the tolerance would not allow this as freely, they would be simple enough to remove/replace. However, even if the washer's inner circumference is not *right on shaft*, having less tolerance for eventually moving can only help. This would give stability but cannot stress how important it is to not use undue downward pressure on ANY encoder/pot as well to avoid calamity. Lastly, never loan your Virus out to anyone in first place  ! !Feedback and criticism on this caffeinated A-ha Moment is most welcome!!

__________________

"Language is a VIRUS from outer space" --Wm. S. Burroughs |

|

«

Previous Thread

|

Next Thread

»

| Thread Tools | Search this Thread |

| Display Modes | |

|

|

All times are GMT. The time now is 12:30 PM.

Powered by vBulletin® Version 3.6.4

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.

Skin Designed by: Talk vBulletin

Copyright ©2000 - 2025, Jelsoft Enterprises Ltd.

Skin Designed by: Talk vBulletin

Copyright ©2002-2022, Infekted.org

|

|

Hybrid Mode

Hybrid Mode