Quote:

Originally Posted by chimney chop

do the aluminum sides seem to play a large role in the strength of the frame?

|

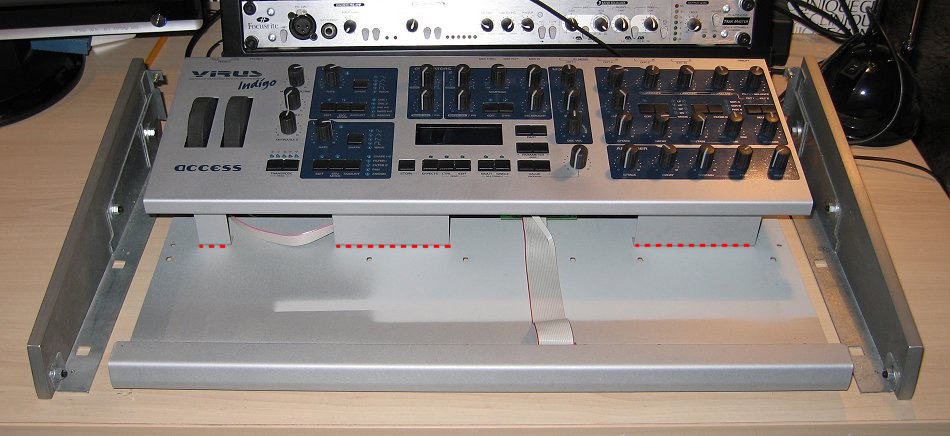

The end 'cheeks' don't really affect the structural integrity of the fascia (the main control panel) as the fascia is mainly bolted to the chassis both at the front and rear, but the cheeks are attached very securely to the chassis itself (along with just one screw at the rear into the back of the fascia, where the jack sockets are). They use perpendicular brackets to fit to the chassis (and rear), as you can see in the following photo:

I think a minimum of three screws are required on the bracket either side attaching the cheeks to the chassis....

And one additional screw on the bracket either side at the back attaching the cheeks to the rear of the fascia too.

No screws are needed along the sides of the cheeks to the fascia, as the fascia is already held solidly down to the chassis via a bracket along the red dotted lines:

If you see my re-potting guide, you will see how it all fits together and what is needed to do so:-

http://infekted.org/virus/showthread.php?t=31443

The aluminium cheeks are aesthetically decent as they show no screws from the outside, even though they have brackets attached to them on the inside.

If you wished to replace the metal cheeks with wood, I think the most trickiest issue would be how to attach the brackets to each wooden cheek securely. You'd need really dense wood, I think, unless you drilled through to the outside (to bolt the bracket internally) like they did with the Virus TI|1 desktop:

However, user

DeFex made custom wooden end cheeks for his Virus desktop to make a kinda modular work surface.